Q1.How can I get a Quotation?

1) 3D with stp.(preferred) igs, st.prt. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can helpyoucomplete above for ODM project

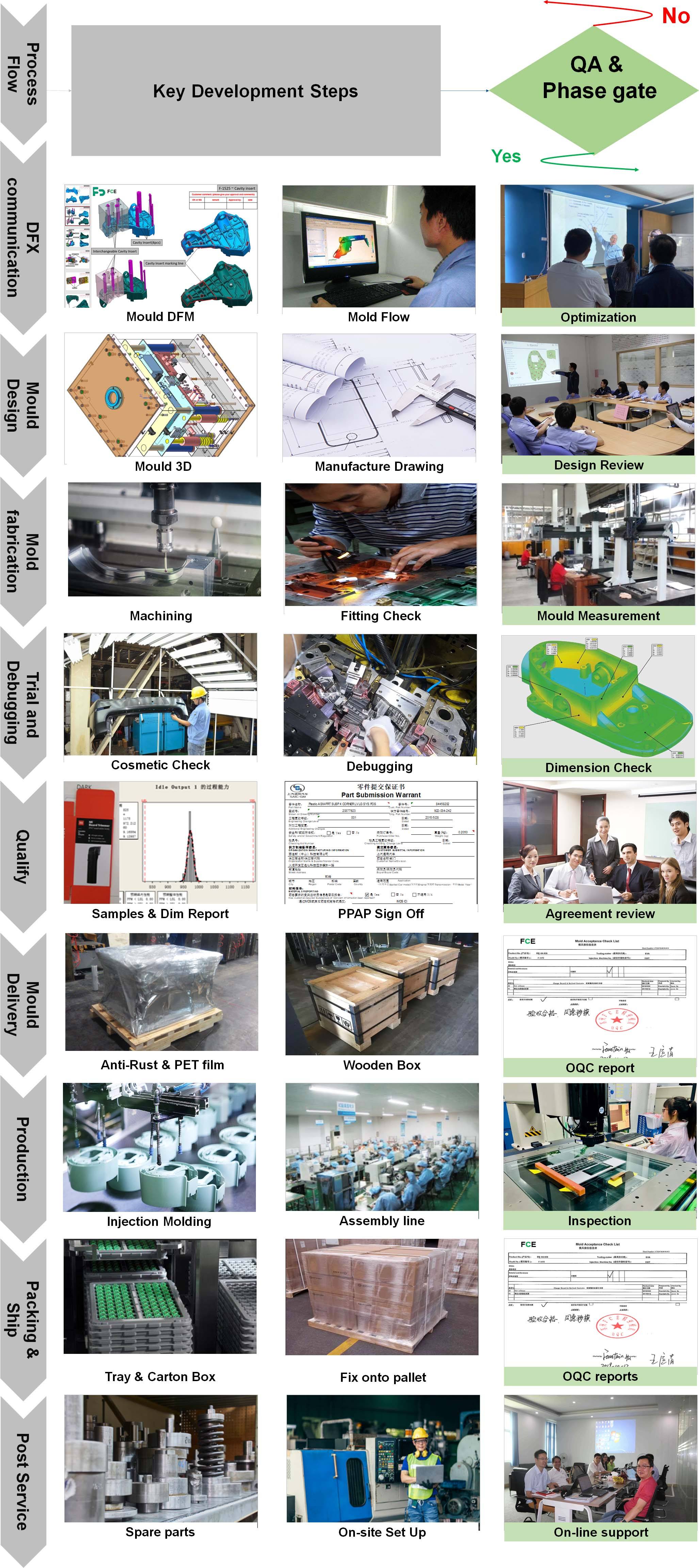

Q2.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some bullet points:

1)Apply APQP Product development process

2)Layemphasis on prevention and planning

3)Once a year ISO9001, IATF 16949 audit and refreshing

4)Designforquality (poke-yoke as much as possible)

Q3. How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, FCE will provide customer 1% discount for one week delay, up limit to 10%

Q4. What is your defective part handling process

FCE have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine defect parts, find out root cause and apply prevention method

1)Quarantine defect batch raw/semi/finish materials

2)Analysis root cause

3)Add prevention and inspection method

4)Produce new part and replace defect part on customer site