The basic concept of SLS is similar to that of SLA. It uses a moving laser beam to trace and selectively sinter powdered polymer and/or metal composite materials into successive cross-sections of a three-dimensional part. As in all rapid prototyping processes, the parts are built upon a platform that adjusts in height equal to the thickness of the layer being built. Additional powder is deposited on top of each solidified layer and sintered. This powder is rolled onto the platform from a bin before building the layer. The powder is maintained at an elevated temperature so that it fuses easily upon exposure to the laser. Unlike SLA, special support structures are not required because the excess powder in each layer acts as a support to the part being built. With the metal composite material, the SLS process solidifies a polymer binder material around steel powder (100 micron diameter) one slice at a time, forming the part. The part is then placed in a furnace, at temperatures in excess of 900 °C, where the polymer binder is burned off and the part is infiltrated with bronze to improve its density. The burn-off and infiltration procedures typically take about one day, after which secondary machining and finishing is performed. Recent improvements in accuracy and resolution, and reduction in stair-stepping, have minimized the need for secondary machining and finishing. SLS allows for a wide range of materials, including nylon, glass-filled nylon and many metal material.

Capabilities

Material type: Powder (Polymer)

Materials: Thermoplastics such as Nylon, Polyamide, and Polystyrene; Elastomers; Composites

Max part size: 22.00 x 22.00 x 30.00 in.

Min feature size: 0.005 in.

Min layer thickness: 0.0040 in.

Tolerance: 0.0100 in.

Surface finish: Average

Build speed: Fast

Applications: Form/fit testing, Functional testing, Rapid tooling patterns, Less detailed parts, Parts with snap-fits & living hinges, High heat applications

TOP

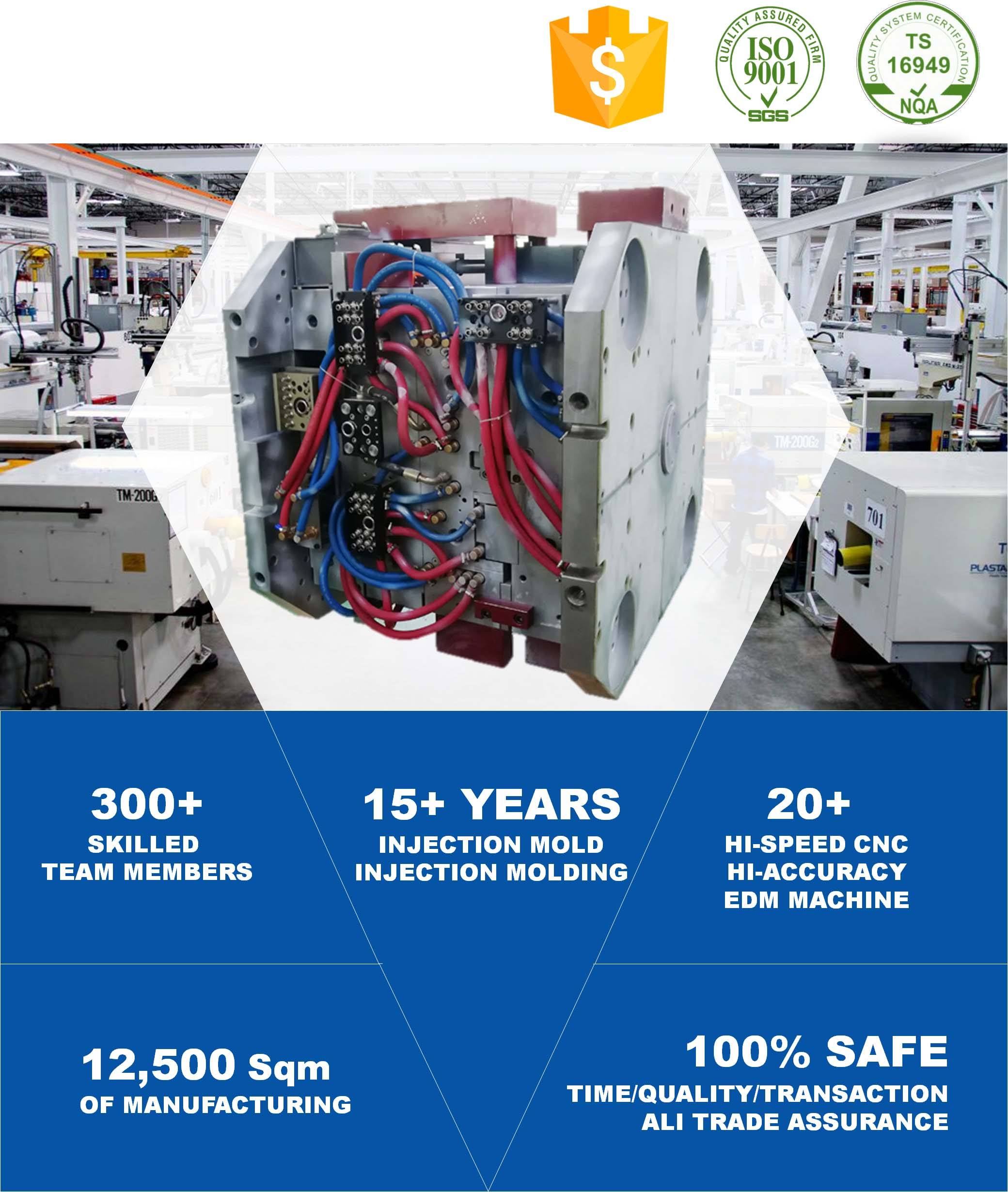

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

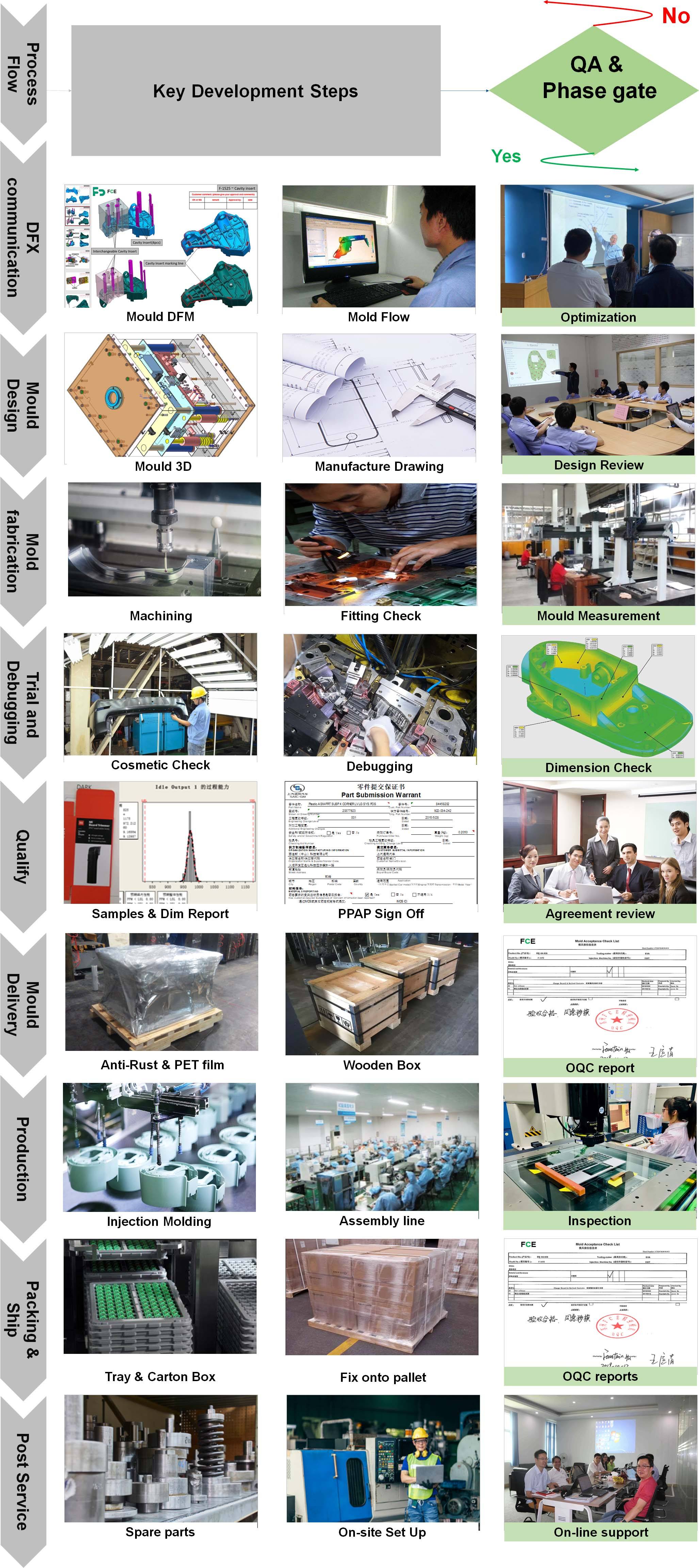

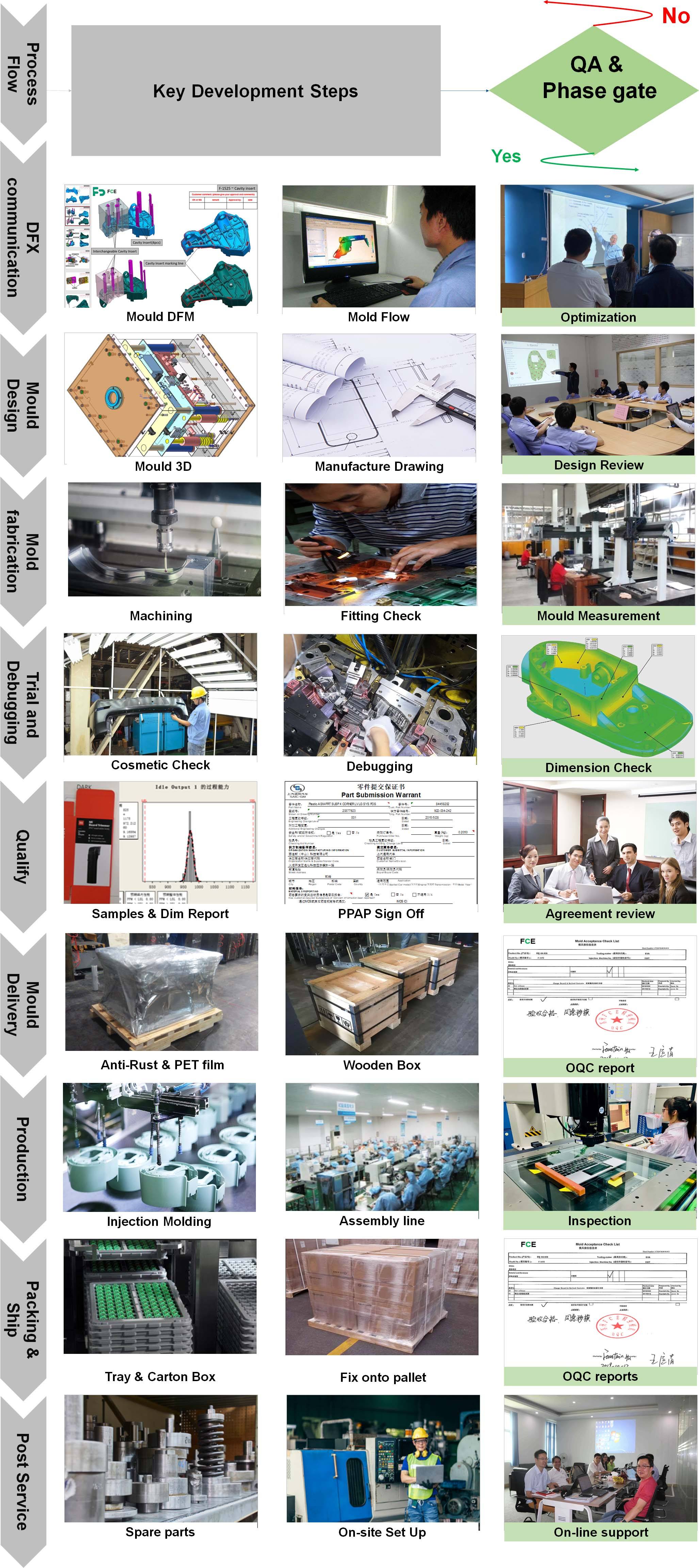

MOLD PROCESS

Where the Good Quality from:

Good Quality Planning, Project Management, Work Procedure, Tracibility

All in our Blood

COMPANY PROFILE

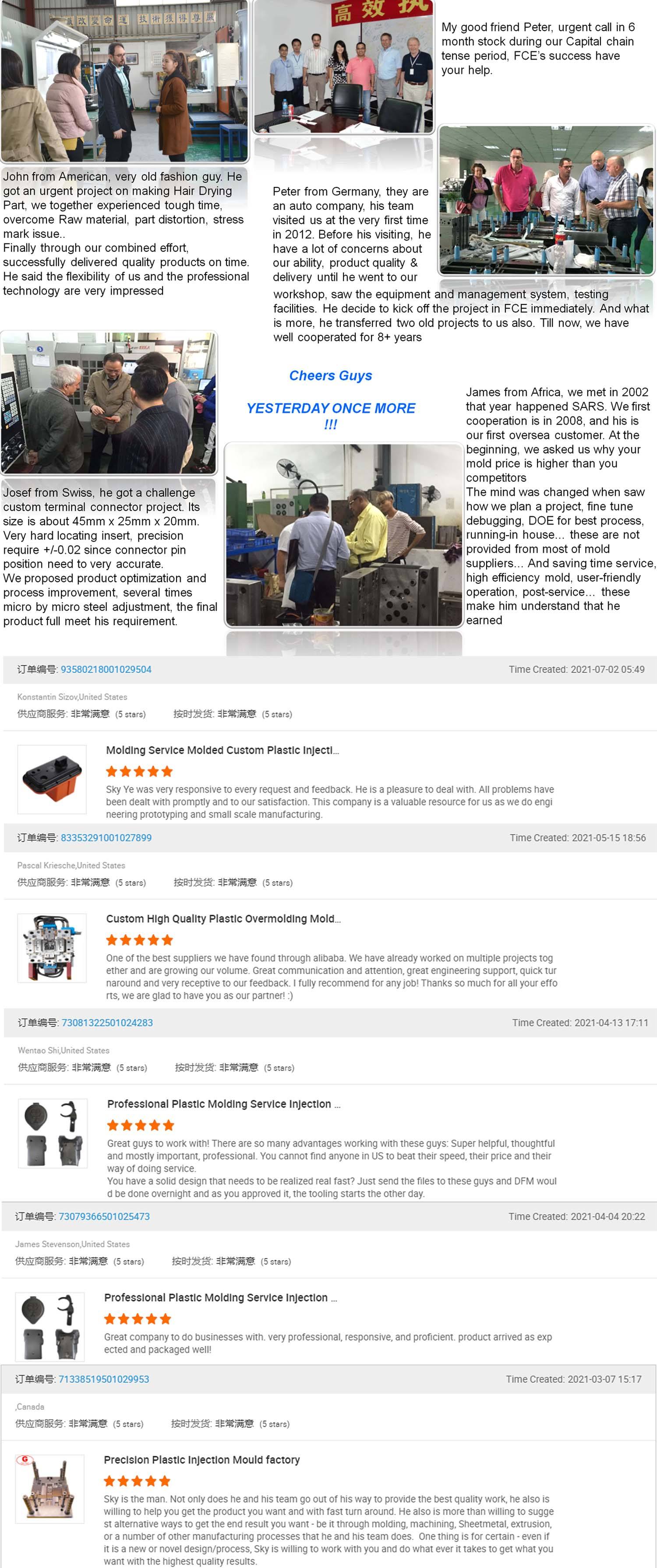

High precision injection moulding and Sheet Metal are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection Molding Services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-K Injection Moulding, liquid silicone rubber, Sheet Metal Processing, Custom Machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

We use our project management skill to create a structured phase-gate process. This establishes your goals and expectations and ensures that you have the oversight and impetus to reach a positive outcome.

The injection Molding, metal stamping, sheet metal processing, machining factories are certificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485