Compression overmolding Rubber Silicone material Service

Get Latest Price| Payment Type: | L/C,T/T,MoneyGram,PayPal |

| Min. Order: | 1 Set/Sets |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Select Language

| Payment Type: | L/C,T/T,MoneyGram,PayPal |

| Min. Order: | 1 Set/Sets |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Brand Name: Fce

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

Processing Technic: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Measurement Equipment: Cmm, Vmm, 3d Scan, Gloss Meter, Colour Meter,

Machine Tonnage: 35ton To 2000ton

Machine Types: Hydraulic, Vertical, Multi-K, Powder Injection

Material Experience: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colors Available: Customized Compounded Resin To Pantone Code Or Colour Plaque

Production Working Time: 7x24hrs

Delivery Time: 25days

Place Of Origin: Jiangsu, China

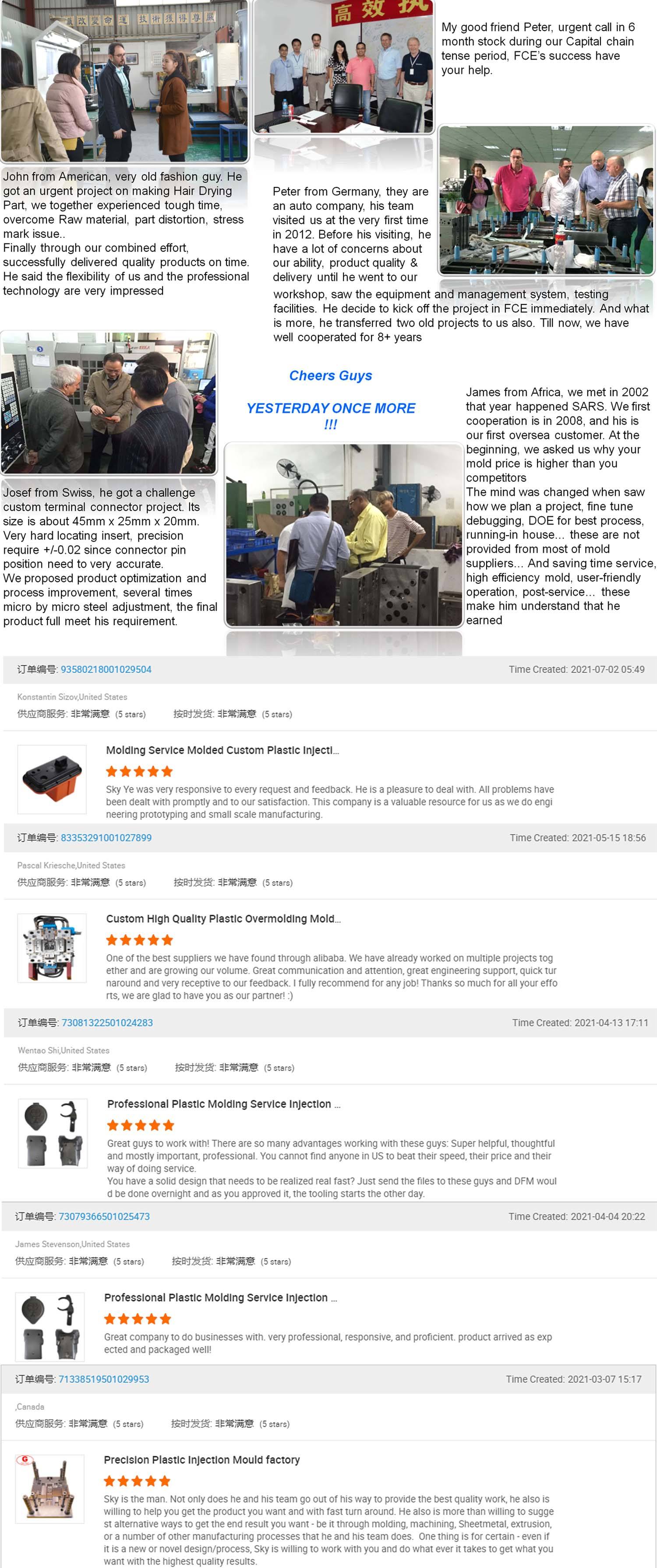

FCE has provided industry-leading Injection Molding services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-K Injection Moulding, liquid silicone rubber, Sheet Metal Processing, Custom Machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

PRODUCTS DESCRIPTION

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

Where the Good Quality from:

Good Quality Planning, Project Management, Work Procedure, Tracibility

All in our Blood

High precision injection moulding and Sheet Metal are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection Molding Services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-k Injection Moulding, liquid silicone rubber, Sheet metal processing, custom machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

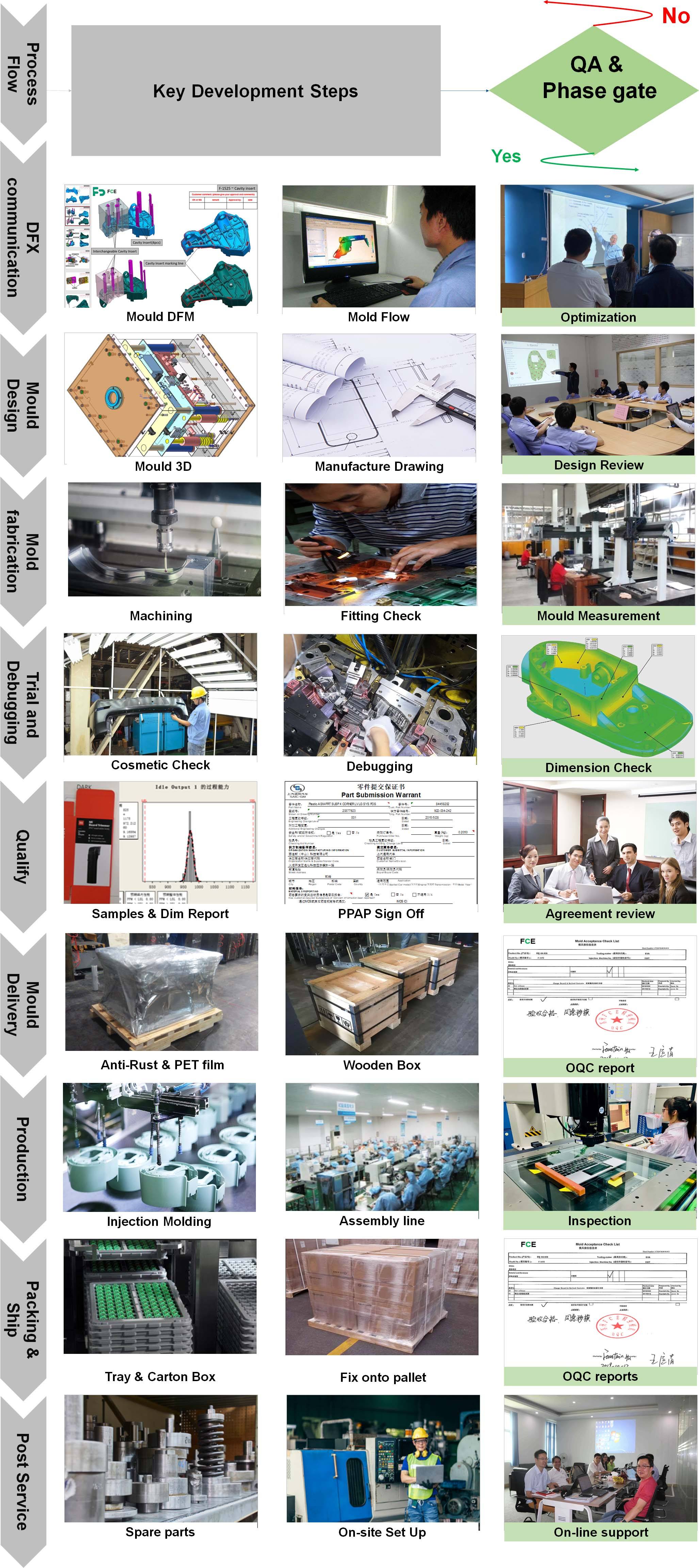

We use our project management skill to create a structured phase-gate process. This establishes your goals and expectations and ensures that you have the oversight and impetus to reach a positive outcome.

The injection Molding, metal stamping, sheet metal processing, machining factories are ceritificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485

Q1.How can I get a Quotation?

1) 3D with stp.(preferred) igs, st.prt. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can helpyoucomplete above for ODM project

Q2.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some bullet points:

Q3. How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, Goutech will provide customer 1% discount for one week delay, up limit to 10%

Q4. What is your defective part handling process

Goutech have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine defect parts, find out root cause and apply prevention method

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.