Brand: FCE

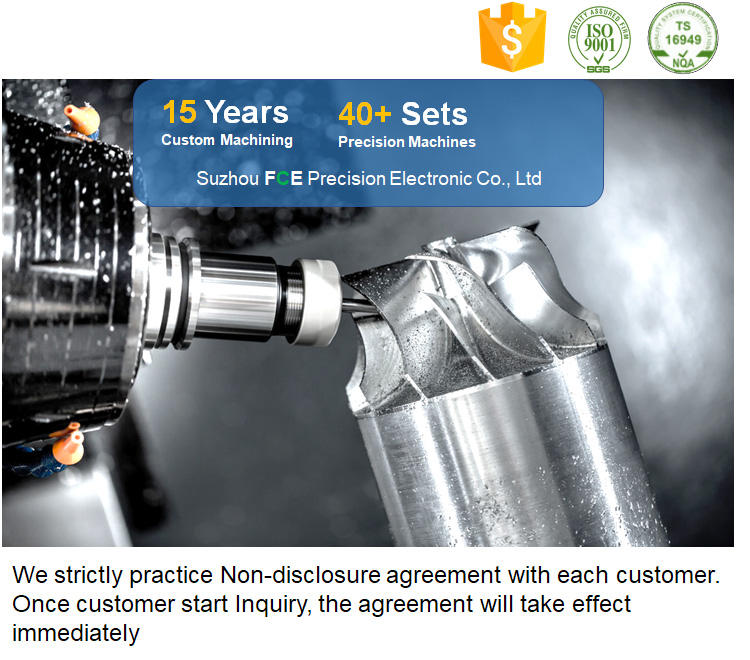

CNC Machining Or Not: Cnc Machining

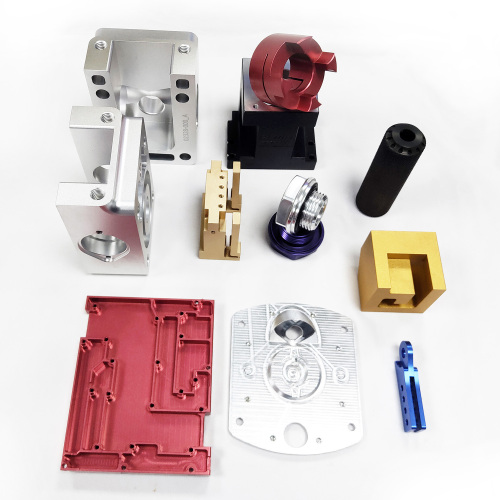

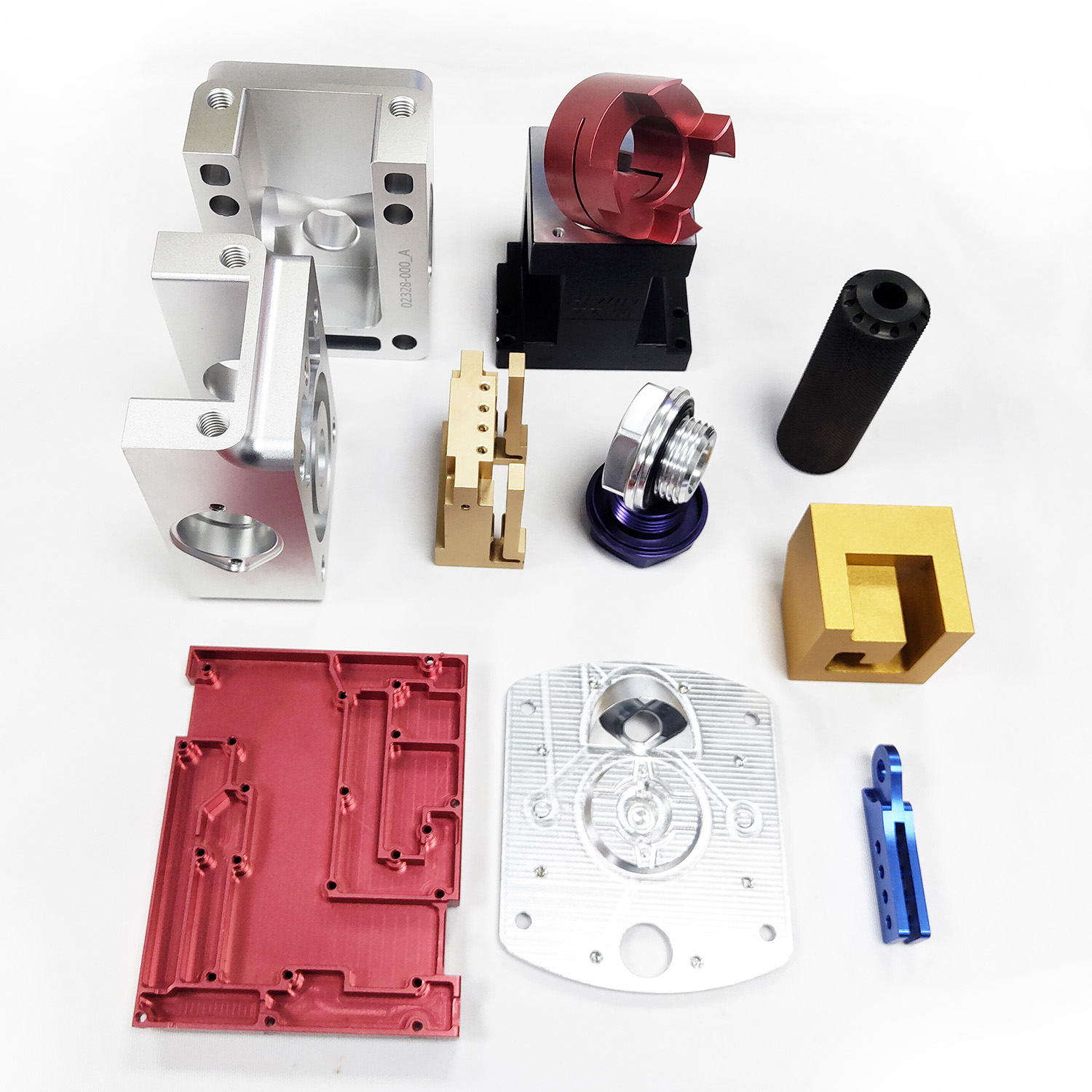

Type: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire Edm, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining Or Not: Micro Machining

Model Number: Oem

Brand Name: FCE

Product Name: CNC Mchining Parts

Tolerance: ±0.01mm

Surface Treatment: anodizing/polishing/plating/painting

Service: packaging Assembly services

Certification: ISO9001/TS16949/QS/ISO14001

Logo: Accept Custom Logo

Oem/odm: OEM ODM CNC Machining Service

Lead Time: 10-20 Days

Types Of: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire Edm, Rapid Prototyping

Machinable Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Place Of Origin: Jiangsu, China

Whether CNC Machining: Cnc Machining

Whether Micro Processing: Micro Machining

Place Of Origin: China