automotive plastic injection molding

$1.51-999 Piece/Pieces

$1.21000-9999 Piece/Pieces

$1≥10000Piece/Pieces

| Payment Type: | Western Union,T/T,MoneyGram,PayPal |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Select Language

$1.51-999 Piece/Pieces

$1.21000-9999 Piece/Pieces

$1≥10000Piece/Pieces

| Payment Type: | Western Union,T/T,MoneyGram,PayPal |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Brand: FCE

Brand Name: Fce

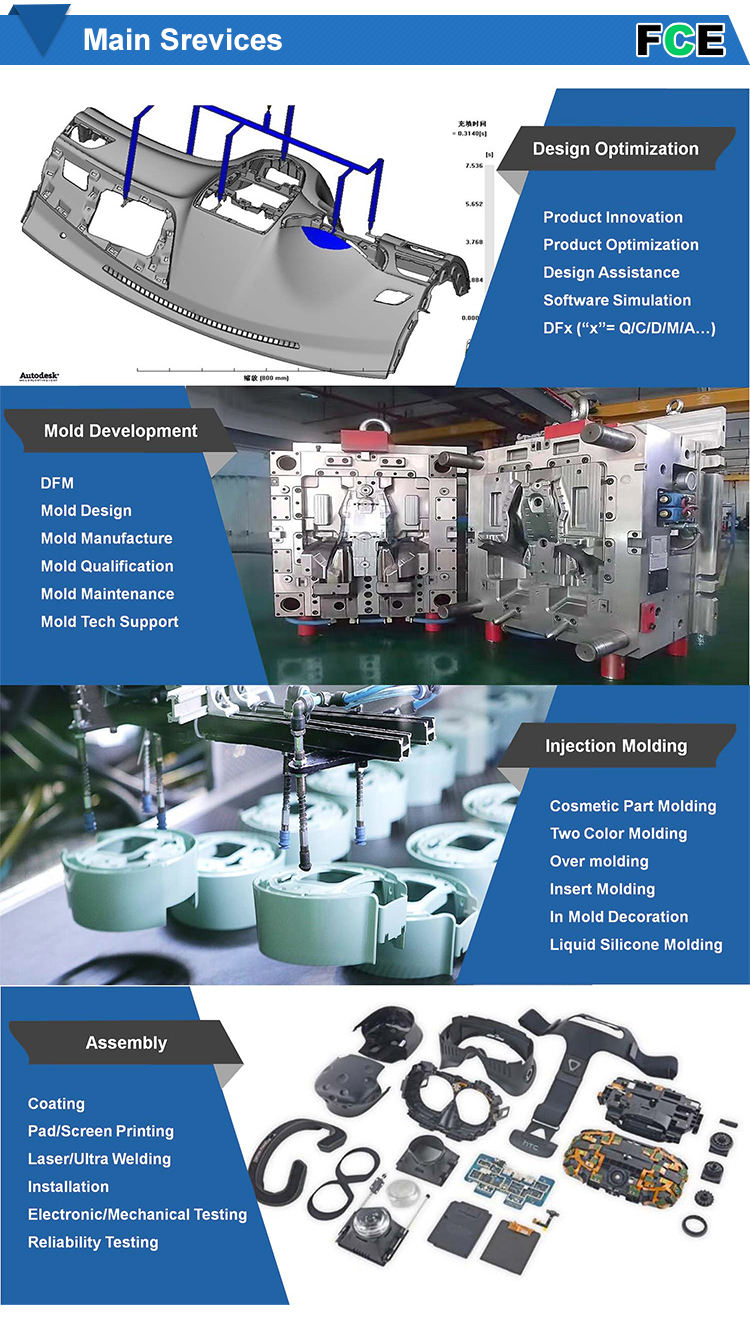

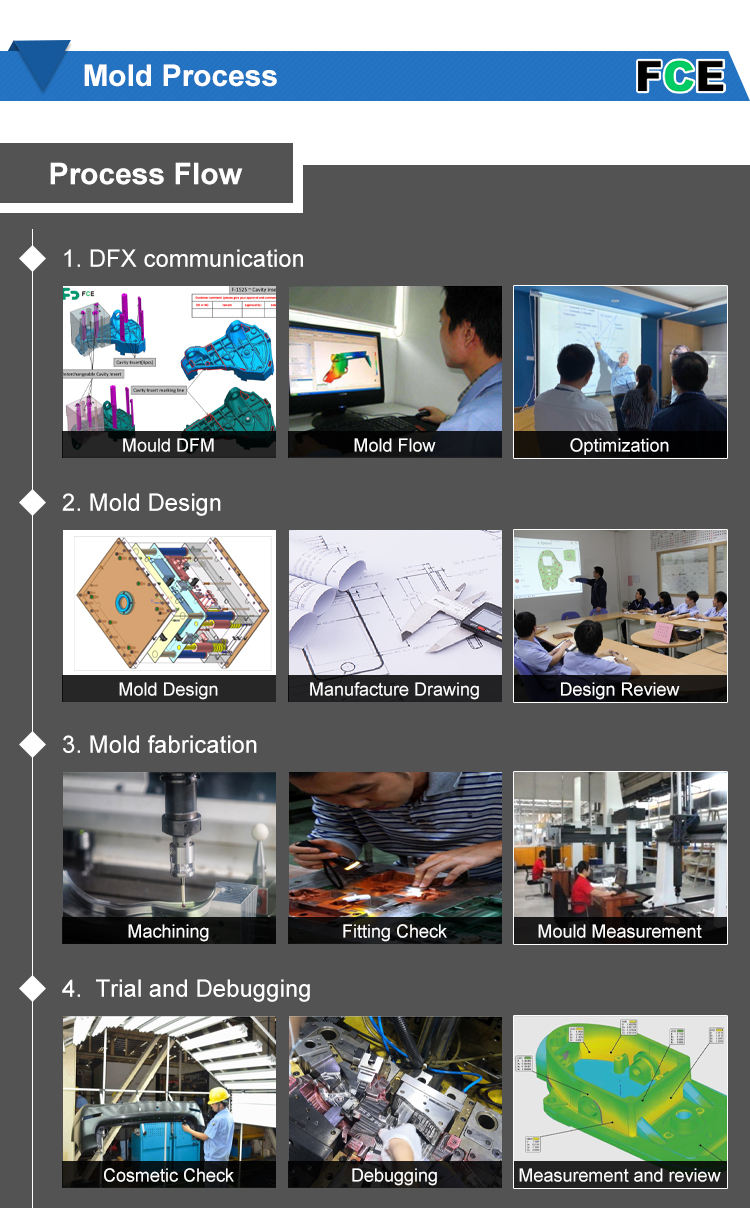

Shaping Mode: Plastic Injection Mould

Product Material: Plastic, Rubber, Metal, Aluminium, Copper

Product: Household Appliance, Vehicle Mould, Household Product

Processing Technic: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

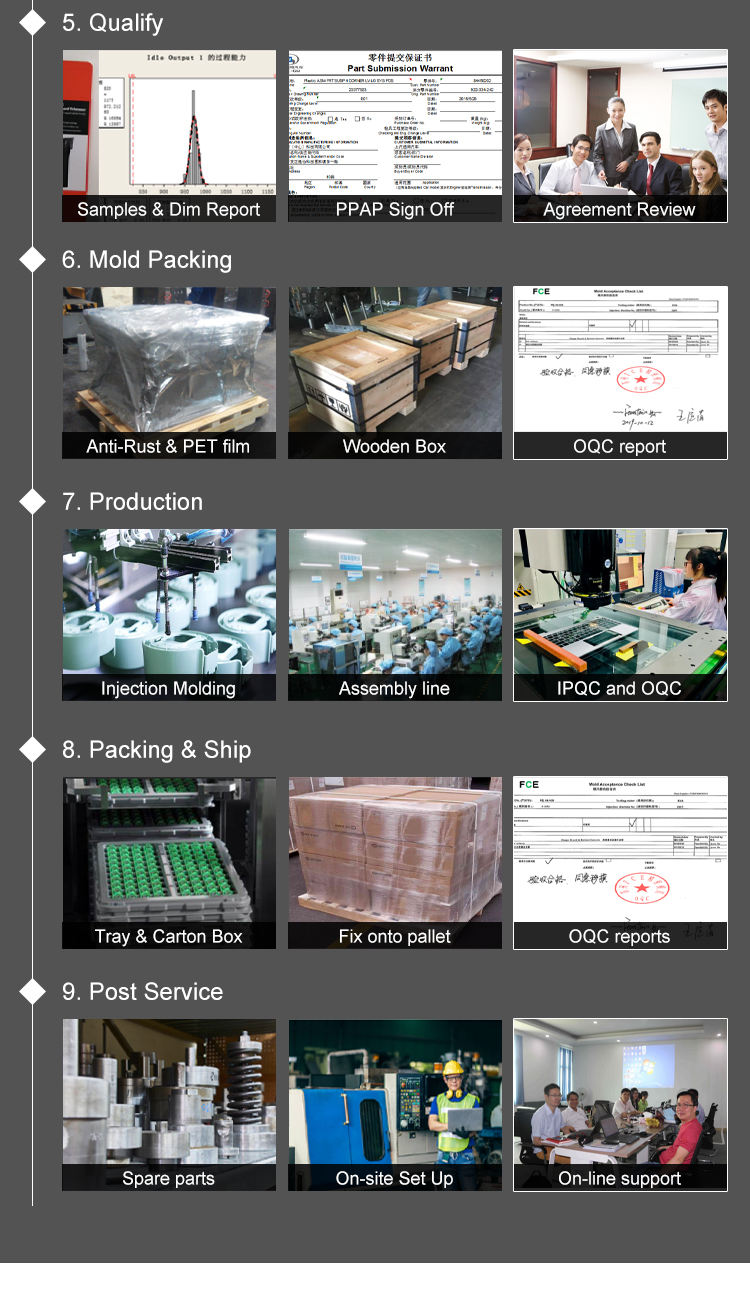

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Measurement Equipment: Cmm, Vmm, 3d Scan, Gloss Meter, Colour Meter,

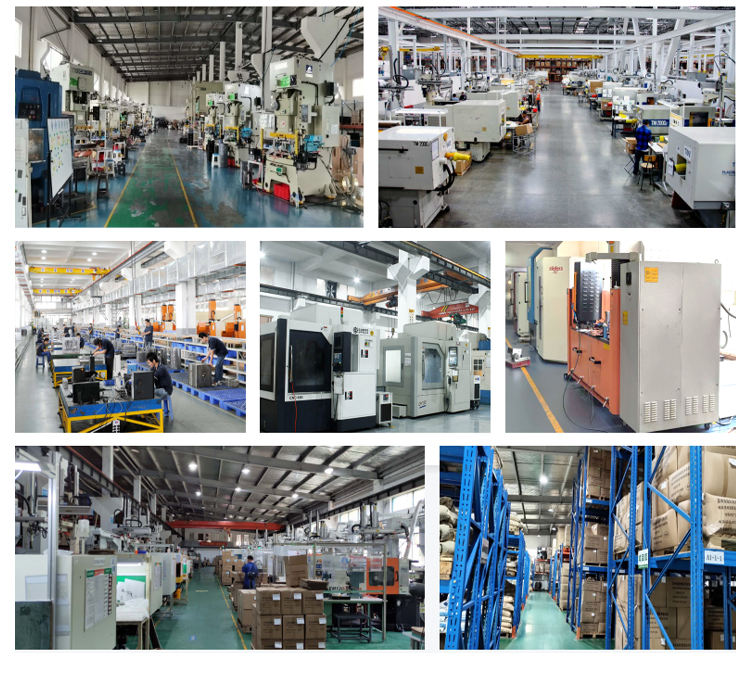

Machine Tonnage: 35ton To 2000ton

Machine Types: Hydraulic, Vertical, Multi-K, Powder Injection

Material Experience: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colors Available: Customized Compounded Resin To Pantone Code Or Colour Plaque

Production Working Time: 7x24hrs

Delivery Time: 25days

Place Of Origin: Jiangsu, China

Forming Method: Plastic Injection Mould, Plastic Extrusion Mould, Silicone Mould, Blowing Mould, Extrusion Mould, Compression Mould

The basic mechanism of the technology is rather simple. At first, the machine injects molten plastic into a metal mold. Inside the mold, the liquid plastic eventually cools and hardens. Once the plastic is no longer molten, the metal mold separates into two, revealing the finished plastic product inside.

Despite this simplicity in the fundamental process, this technology is highly efficient. The probability of error is minimal. Manufacturers and industrialists around the globe rely on Injection Molding to produce quality goods with consistency.

Advantages

100+ materials

We offer many available injection molding material, also customizable

Accuracy & Efficiency

All Sheet Metal Parts are built on-demand and with lower setup costs compared to Cnc Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Scalability

Molding can be the ideal process for custom production runs of 1-500,000+ parts.

Stable & Durable

Injection mold produces real end products that has awesome durability.

Rapid Turnaround

With rapid molding, molds ready in 15 days, parts shipped in 1 to 15 days

Surface Quality

Injection molds are precisely CNC milled and polished, which gives the parts terrific surface, customizable treatments are also available.

Disadvantages

Structure Limits

Interlocking and hollowed structure is difficult to be produces in one pieces with Injection Molding.

Startup Cost

For small batch production, the starting cost is not as affordable as CNC Milling or 3D Printing.

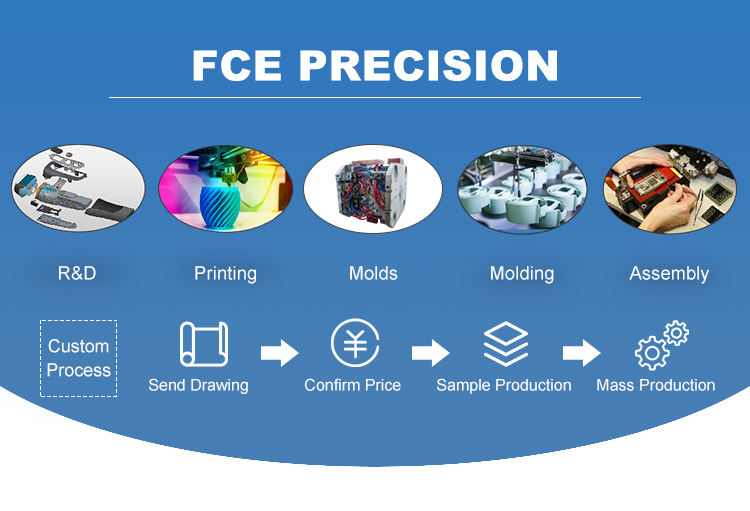

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Injection Molding Parts, Sheet Metal Processing, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.