plastic injection molding companies

$0.01-1 /Piece/Pieces

| Payment Type: | Western Union,T/T,L/C,MoneyGram,PayPal |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai/Ningbo |

Select Language

$0.01-1 /Piece/Pieces

| Payment Type: | Western Union,T/T,L/C,MoneyGram,PayPal |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai/Ningbo |

Brand: FCE

Forming Method: Plastic Injection Mould, Blowing Mould, Plastic Extrusion Mould, Compression Mould, Silicone Mould

Product Material: Plastic, Rubber, Metal, Steel, Aluminium, Iron, Copper

Product: Household Product

Shaping Mode: Plastic Injection Mould

Delivery Time: 25days

Brand Name: Fce

Processing Technic: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Measurement Equipment: Cmm, Vmm, 3d Scan, Gloss Meter, Colour Meter,

Machine Tonnage: 35ton To 2000ton

Machine Types: Hydraulic, Vertical, Multi-K, Powder Injection

Material Experience: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colors Available: Customized Compounded Resin To Pantone Code Or Colour Plaque

Production Working Time: 7x24hrs

Place Of Origin: Jiangsu, China

Injection Molding is a manufacturing process commonly used in creating plastic components. In brief this process involves injecting liquid plastic into a two piece mold. This plastic is allowed to cool within the mold and then the solidified plastic is ejected and you have your part.

Plastic Injection Molding is the preferred process for manufacturing plastic parts. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. It is ideal for producing high volumes of plastic parts due to the fact that several parts can be produced in each cycle by using multi-cavity injection molds. Some advantages of injection molding are high tolerance precision, repeatability, large material selection, low labor cost, minimal scrap losses, and little need to finish parts after molding. Some disadvantages of this process are an expensive upfront tooling investment and process limitations.

Advantages of injection molding plastic

Complex Geometry

Perhaps one of the most significant advantages of Plastic Injection molding is the fact that this method of manufacturing is incredibly well-suited for producing detailed and complex parts geometries.

Production Efficiency

In addition to providing excellent results for complex and detailed parts, plastic injection molding also offers the benefit of considerable production efficiency

Increased Part Strength and Durability

Quick turnaround times do not come at the expense of quality, as is evident with AIM’s plastic injection molded parts

Material Flexibility

Material flexibility does not necessarily mean that the plastic parts themselves will be flexible, but rather, it means that this method of production is adaptable to the types of materials that can be used for your project

Automation to Save Manufacturing Costs

Just as plastic injection molding saves time through automation, plastic injection molding also saves significant costs.

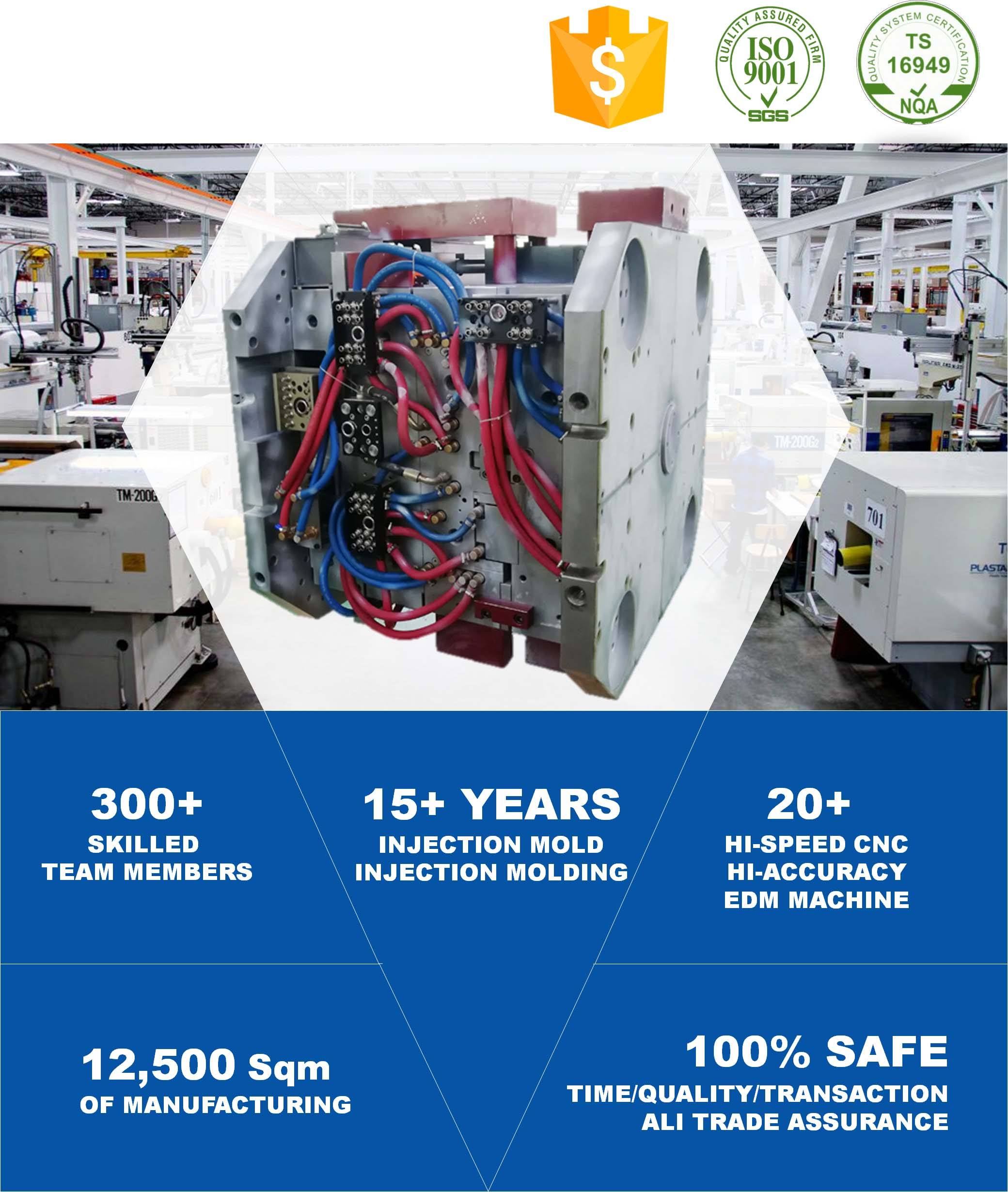

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection molding services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, multi-k injection moulding, Sheet metal processing, custom machining.

High precision injection moulding and Machining are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.