products made by injection moulding

Get Latest Price| Payment Type: | L/C,T/T,MoneyGram,PayPal |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Select Language

| Payment Type: | L/C,T/T,MoneyGram,PayPal |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shanghai/Ningbo |

Brand Name: Fce

Shaping Mode: Plastic Injection Mould, Injection Moulding

Product Material: Plastic

Product: Vehicle Mould

Process: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

2nd Process Outsource: Electro-Plating, Plasma, Ed Etc.

Machine Tonnage: 35ton To 2000ton

Machine Type: Hydraulic, Vertical, Multi-K, Powder Injection

Material: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colour: Customized Compounded Resin To Pantone Code Or Colour Plaque

Delivery Time: 30days

Place Of Origin: Jiangsu, China

Plastic Injection Molding is a technical method to make various forms of plastic (powder, particle, solution and dispersion) into products or billets in the desired shape. At present, there are more than 30 kinds of Plastic Molding process. For example, the commonly used methods for processing thermoplastics are extrusion, Injection Molding, calendering, blow molding and hot molding. Thermosetting plastics are usually processed by molding, transfer molding, and injection molding.

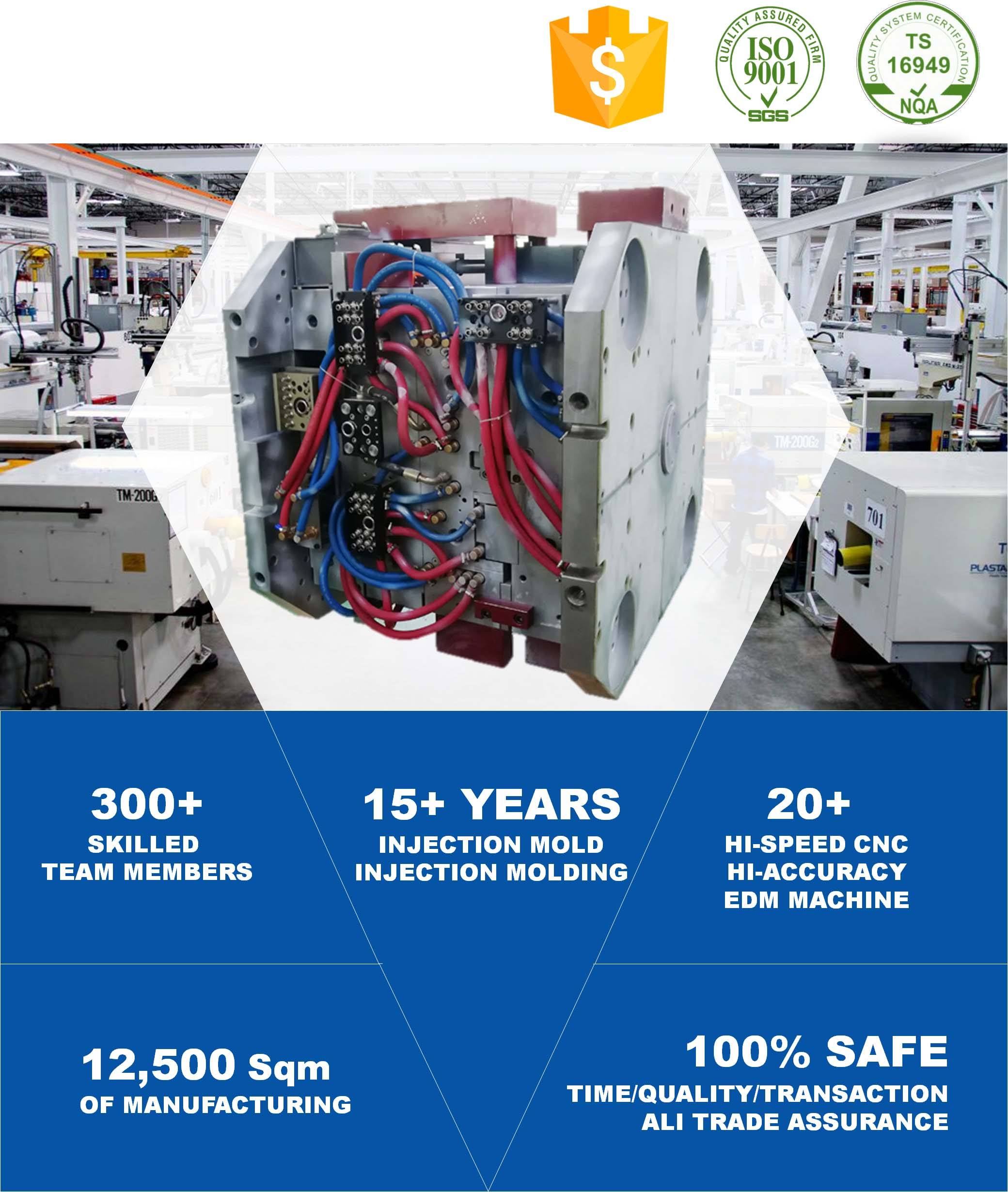

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

Where the Good Quality from:

Good Quality Planning, Project Management, Work Procedure, Tracibility

All in our Blood

The injection Molding, metal stamping, Sheet Metal Processing, machining factories are ceritificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.